EP 1110-2-12

30 Sep 95

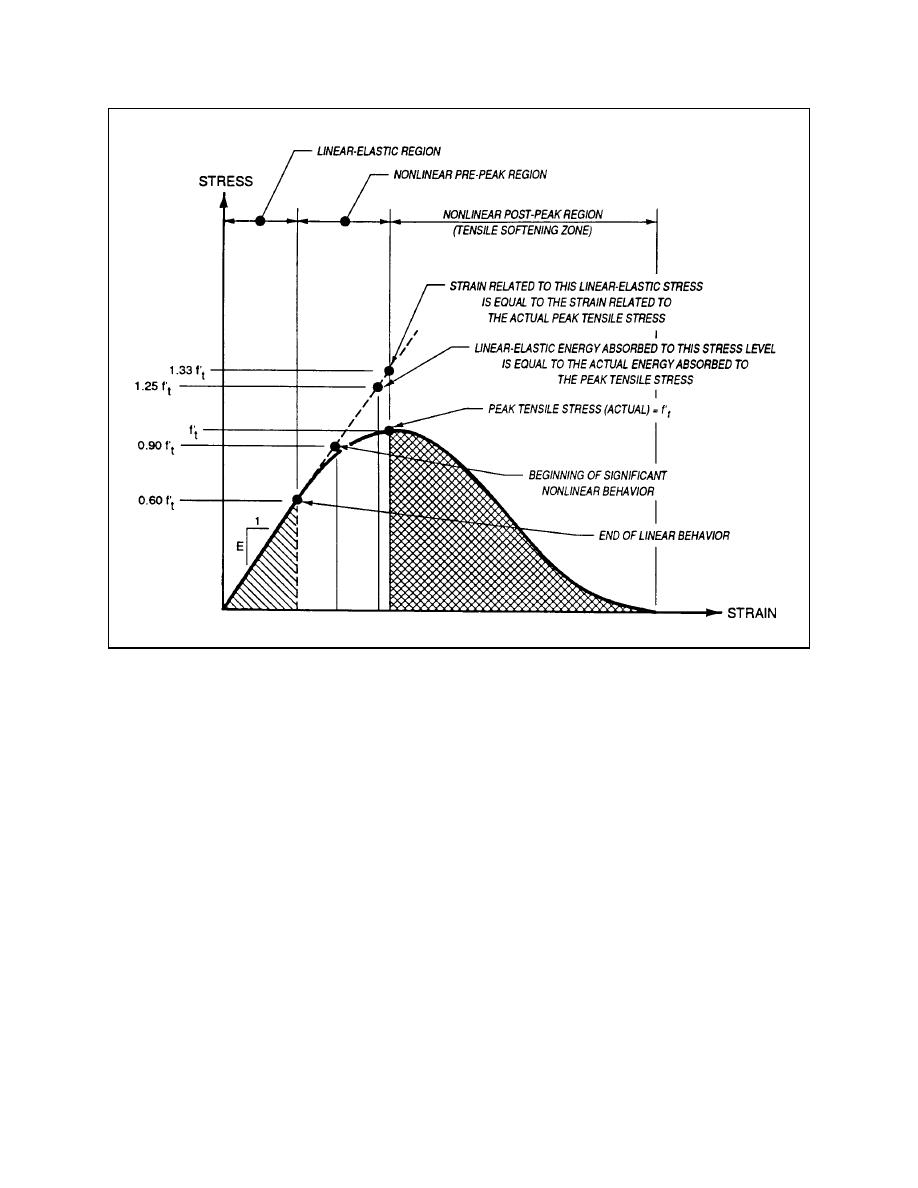

Figure 3-7. Tensile stress/strain diagram for RCC

this point, the response can still be judged as primar-

b. Key points on stress/strain curve. Several

ily linear.

points on the stress/strain curve are of interest when

establishing the allowable tensile stresses that are

(3) ft = 1.25 f ′t -- the area under the dashed line

used in linear-elastic analyses (refer to para-

graphs 4-2c and 4-3c). Based on f ′t = actual peak

for linear-elastic behavior up to this stress level is

approximately equal to the area under the solid line

tensile stress (tensile stress that corresponds to that

for the actual stress/strain curve up to the peak tensile

which would be attained by a direct tensile strength

stress point (this point is the end of microcracking

test), and ft = the stress level based on linear-elastic

and the beginning of macrocracking). Thus, the

behavior (refer to the dashed line in Figure 3-7), the

energy absorbed in a linear-elastic analysis to this

following key values of ft are of interest:

point of stress is equal to the actual energy absorbed

(1) ft = 0.60 f ′t -- the end of the elastic range

through the microcracking pre-peak region.

and the beginning of microcracking.

(4) ft = 1.33 f ′t -- the strain corresponding to this

(2) ft = 0.90 f ′t -- this point was selected because

point of stress based on linear-elastic behavior is

equal to the strain corresponding to the actual peak

the stress/strain dashed line for linear-elastic behavior

tensile stress. This strain point signifies the end of

is just beginning to significantly separate from the

microcracking and the beginning of macrocracking.

actual stress/strain curve. If the tensile stresses for a

This point also represents a practical limit for the

linear-elastic analysis stay within the stress level for

3-8

Previous Page

Previous Page