EP 1110-2-12

30 Sep 95

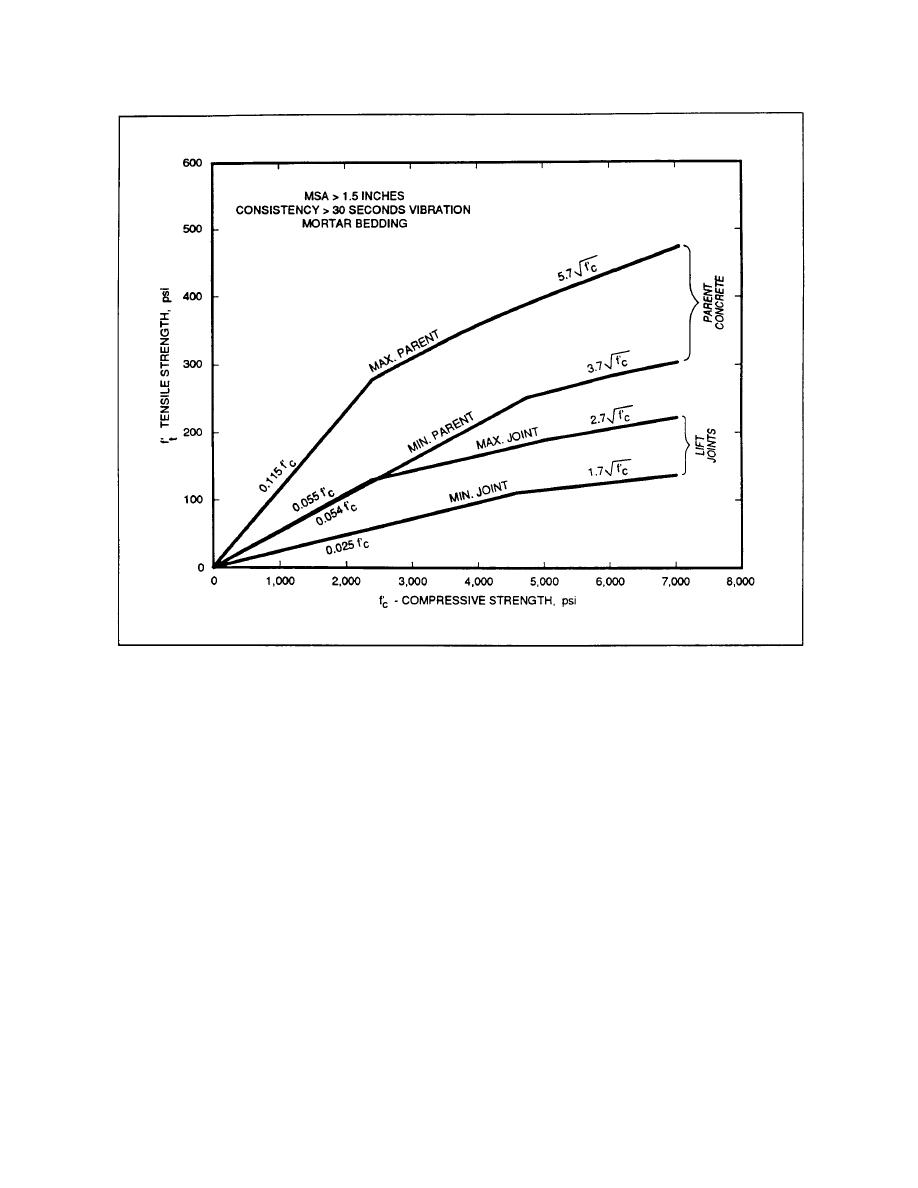

Figure 3-4. Tensile strength range, RCC, MSA > 1.5 inches, consistency > 30 seconds vibration, mortar

bedding

3-7.

Tensile Stress/Strain Relationship

respect to the peak stress or ultimate capacity. In

tension, it is a different matter since tensile stress can

approach and exceed the peak tensile stress capacity

As mentioned in paragraph 2-2b, concrete cracking,

of the concrete and in some cases cracking will

crack propagation, and the energy dissipated in the

occur.

process are complex and nonlinear in nature. For a

simplified linear-elastic analysis, a constant modulus

b. Tensile stress/strain curve. The actual non-

of elasticity is required. Thus, a linear stress/strain

relationship is used for the analysis with a tensile

linear stress/strain relationship for RCC concrete is

modulus equal to the modulus of elasticity for con-

shown in Figure 3-7. The assumed linear relationship

crete in compression.

used for finite element analysis was developed from

the work done by Raphael (1984). The actual nonlin-

ear performance of concrete in tension consists of a

a. Compression and tension differences.

linear region from zero stress up to 60 percent of the

Although a linear relationship is assumed for the

peak stress, a nonlinear ascending region from

analysis, in actuality the stress/strain relationship

60 percent of peak stress to peak stress (this point on

becomes nonlinear after concrete stresses reach

the curve corresponds to the direct tensile strength

approximately 60 percent of the peak stress (Raphael

test value described in paragraph 3-3c), and a nonlin-

1984). In compression this does not cause a problem

ear descending region from peak stress back to zero

because, in general, concrete compressive stresses

even during a major earthquake are quite low with

3-5

Previous Page

Previous Page