U.S. Army Engineers in the Gulf War

in generators and provided running water. The road construction element had

been taken out of the contract, but the contractor had built crude roads to bring

in his equipment. The contractor worked on roads for 60 days and used what

amounted to a platoon's worth of equipment-four dump trucks, two

bulldozers, a bucket loader, a road grader, and compaction equipment-adding

considerably to his cost.19 Given the amount of work that the contractor

performed and his expenses, the costs of the life support areas were probably

reasonable.

Main Supply Routes

The construction of main supply routes was critical for logistics support and

for moving troops. Initially engineers paid little attention to theater planning for

main supply routes because the existing highway network in Saudi Arabia gave

adequate support during the initial deployment phase. Main supply route Audi,

a good multilane road, stretched from Dhahran along the coast to just north of

Jubail. Dodge (T a pl ine Road) ran northwest from Audi to Hafar al Batin and

then across Saudi Arabia. Two major southern routes were Toyota and Nash.

Toyota was an excellent multilane road that ran between Dhahran and Riyadh,

and Nash ran north from Riyadh to Hafar al Batin where it intersected with

Dodge. Some roads were in good shape initially, but none could withstand the

high volume of military traffic. Few secondary roads existed. Forward logistics

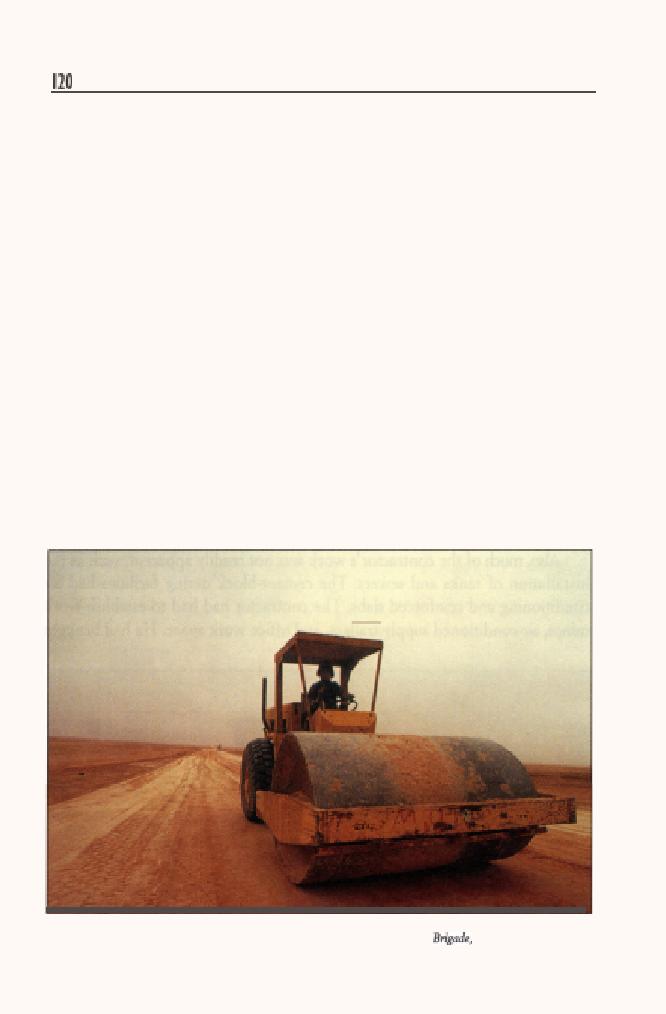

Soldiers from the 20th Engineer Brigade compact the ground for a new road in Southwest Asia.

(U.S. Army photo by SSG Martello, 20th Engineer

Public Affairs Office)

Previous Page

Previous Page