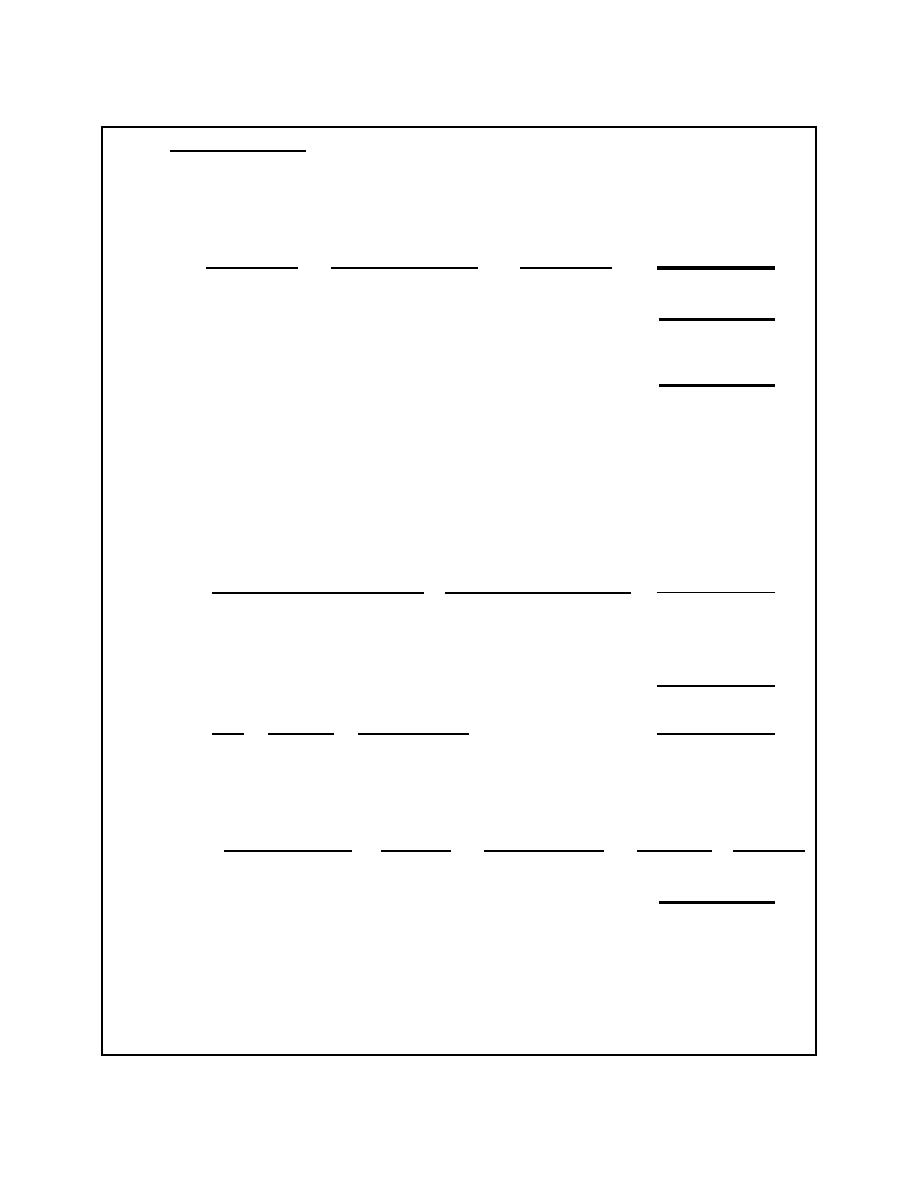

EP 1110-1-8

(Vol. 10)

31 July 03

5.

OPERATING COST (Continued)

(2) Carrier:

(FOG Factor) x (Carrier Fuel Cost) x (LAF)

[1.c.(8)]

[5.a.(2)]

[Appendix B]

) x ($4.13

/hr) x (1.23

)

=$

/hr

(0.276

1.40

(3) Total Hourly FOG Cost:

Total [5.b.]=$

/hr

4.40

[(5.b.(1)] + [5.b.(2)]

c.

Alternative Fuel/FOG Cost:

Total [5.c.]=$

/hr

0.00

(See chapter 2, paragraph 24.d. for guidance on when to use.)

d.

Repair Cost:

(1)

Economic Adjustment Factor (EAF):

(EK is from [1.c.(1)])

(Economic Index for Year 1.a.(3)) / (Economic Index for Year 1.a.(4))

[Appendix E]

[Appendix E]

) / (5,310

)=

1.079(EAF)

(5,729

(See table 3-1 for last year of economic life.)

(2)

Repair Factor (RF):

(RCF) x (EAF) x (LAF)

=

Repair Factor (RF)

[1.c.(10)]

[5.d.(1)]

[Appendix B]

(0.90 ) x (1.079

) x (1.23

)

=

1.194 (RF)

(3)

Repair Cost:

[(TEV) - [(TCI) x (Tire Cost )]] x (RF) / (LIFE)

[2.c.]

[4.a.(1)]

[1.a.(9)(d)]

[5.d.(2)]

[1.c.(4)]

) [(0.944

) x ($10,560.00

)]] x (1.194

) / (20,000

)

[($1,172,128.00

/hr

(4)

Total Hourly Repair Cost:

Total [5.d.]=$

69.38

Figure 2-1. Equipment Rate Computation Worksheet

Page 4 of 6

2-16

Previous Page

Previous Page