EP 1110-1-27

27 Jan 00

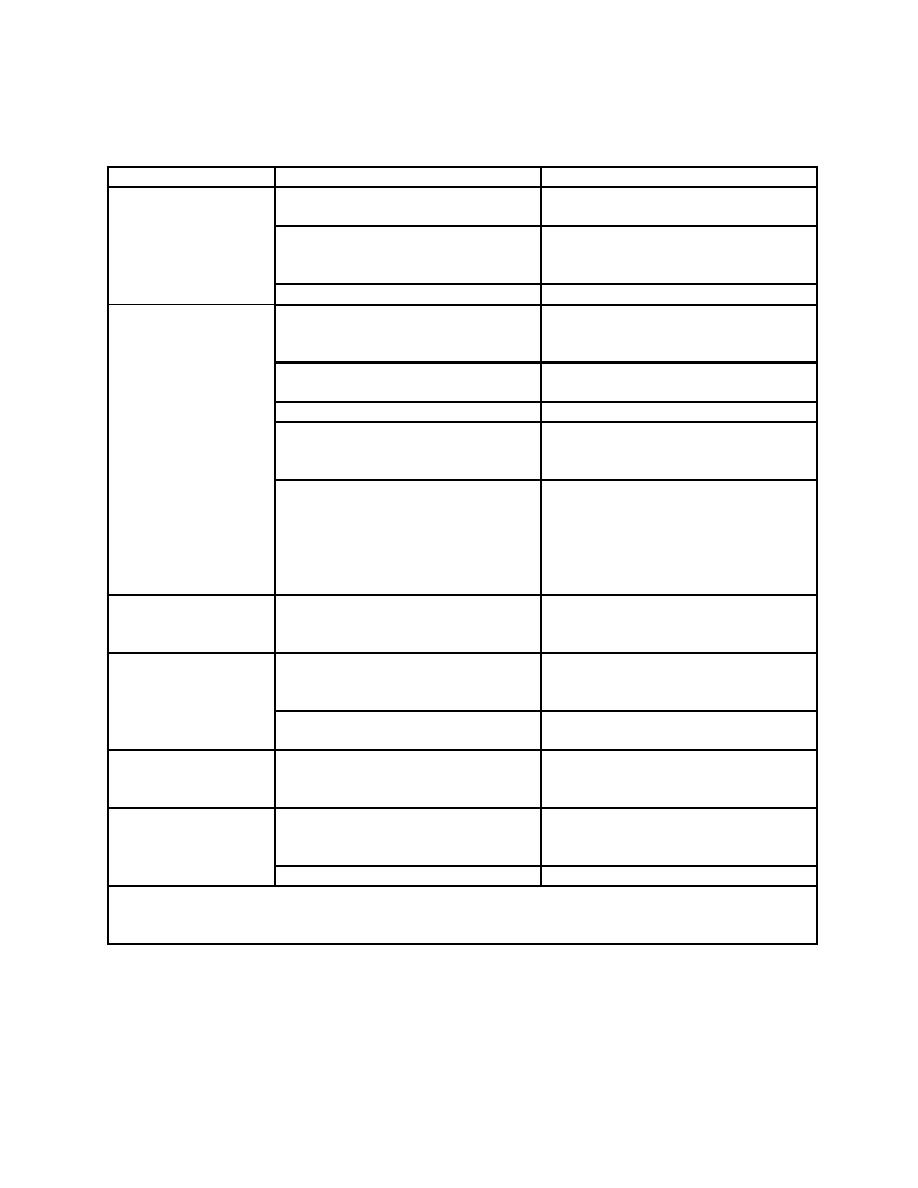

Table 5-1. Minimal First-Year PM Schedule

Maintenance Test

Testing Regime

Time Interval

Physical inspection

Borehole color video

On new wells, then at pump service

intervals

Surface facility inspection. Inspect

Monthly or whenever visited

and clean as needed at sampling

points

Examination of pulled components

As needed, when pulled.

Hydraulic

Well discharge or acceptance

Weekly (recommend installation of

performance

(volume rate and pressure)

automated data collection in

accordance with CEGS 13405)*

Drawdown or head change

Weekly (recommend installation of

automated data collection)

Graphical analysis

Quarterly

Specific capacity test (well hydraulic Annually on selected trouble or

performance) on selected

recommended wells or at

representative wells.

recommended shorter intervals

Pump performance. Conduct step

At least annually or at recommended

shorter intervals if pump service is

"pump" test (Section 2.1) of

centrifugal pumps and similar wear

severe (Q/s and pump test can be a

analysis of positive displacement

single operation). Alternative: In

pumps, compare to "nominal" data.

maintenance system, include triggers

for out-of-nomimal power readings.

System and motor V, A, φ, Ω

Electrical (power)

When visited for service (Recommend

installation of current monitors with

alarms)

Physicochemistry

PH, mV, and temperature

At well start up and quarterly using

project onsite instruments (calibrated)

or routine (laboratory)*

Suspended particulate matter (sand,

At well testing then at pump test

silt, clay)

intervals

Biofouling microbial

BART analyses. After clog-typing,

At well start up for baseline, then

component

pick suitable test type (IRB, SRB, or quarterly on selected representative

SLYM) and monitor for change.

wells.

Treatments and

Well hydraulic improvement and

As testing indicates Q/s or injection

service

pumping systems

rate drops below 90% or pumping

system degrades

In accordance with CEGS 13405

* CEGS 13405 specifies continuous metering, monitoring, and recording equipment for parameters such

as flow, temperature, pressure, and physical-chemical properties of discharged fluids. It does not include

methods for cleaning or other O&M issues.

5-2

Previous Page

Previous Page