EP 1110-1-27

27 Jan 00

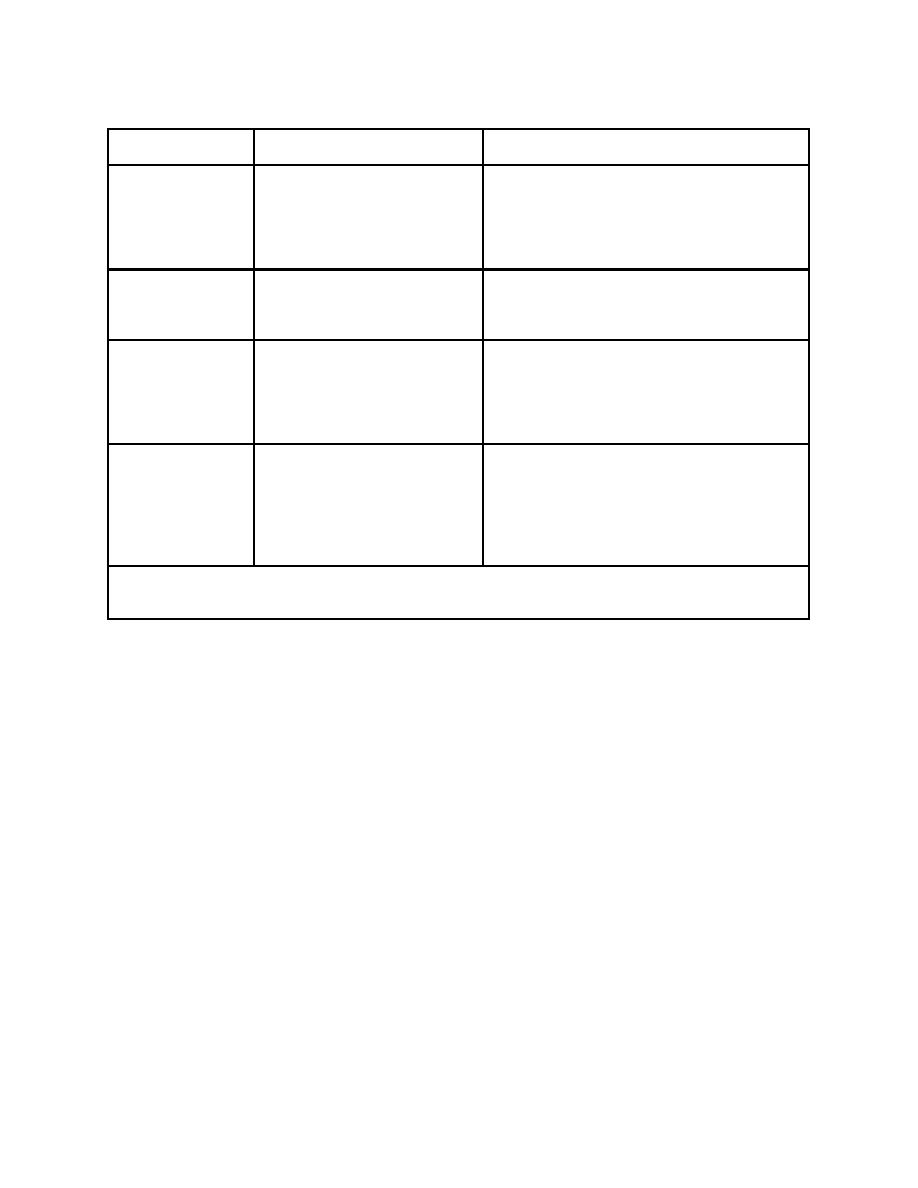

Table 2-3. Features of Water-Level Measurement Methods

Type of water-level

Advantages

Disadvantages

measurement

Requires wellhead access and unobstructed water

Electric sounder

Commonly available, reliable

surface access, probe will foul in floating material

when maintained, accurate under

on water surface, mechanical aging of conductor

most water-only conditions (+0.02

wire must be considered, cross-contamination is

in.), not highly subject to

possible, requires personnel to take levels and

downhole fouling. One sounder

manually enter data.

can be used on multiple wells.

Relatively inaccurate (+1 in. or more), subject to

Airline (gauge

Inexpensive, no need for direct

fouling, requires personnel for taking levels and

measurement) or

access to water level surface, each

manual entry of data.

instrument

well has a dedicated airline.

measurement)

Subject to fouling, requires personnel for taking

Airline (instrument

Inexpensive, no need for direct

levels.

measurement)

access to water level surface, each

well has a dedicated airline. With

instrument, improves accuracy to

electric water-level sounder range.

Data recording possible.

Relatively expensive per unit, requires regular

Water level

Relatively accurate when properly

maintenance to deter fouling. If maintenance not

transducers

selected and maintained, permits

performed, automatic systems may record

automatic data querying in

inaccurate (useless) data.

SCADA* system, dedicated to

well, no personnel exposure to

water, no direct water access

needed.

* Supervisory, control, and data acquisition. Note that all these water level monitoring methods provide data that

can be manually entered into SCADA databases. Note that all conventional water level measurement systems are

fouled by non-aqueous-phase liquids and will yield inaccurate results.

(b) Increases in amperage on start or run cycles over listed service factor amps indicate

Loose terminals in the control box or possible cable defect.

Too high or low service voltage.

Motor windings are shorted.

Mechanical resistance such as sand in bearings.

(c) A drop in typical "run" amperage indicates a loss of mechanical resistance against motor

operation. This datum, in combination with reduced flow and/or pressure data, can be used to confirm that

a problem has developed in pump output, such as if a hole has developed in the pump discharge pipe.

(d) Deviations in circuit ohms indicate wiring problems. Low values on one or more line legs

indicates a potential motor short. Greater-than-normal values indicate poor cable connections or joints, or

windings or cables may be open. If some values are higher than normal and others lower than normal,

drop leads may be mixed.

(e) Megaohm detections outside the circuit indicate ground faults. For a motor installed in a well,

if resistance between any wire lead and true ground is <0.5 MΩ, motor damage is likely to have occurred.

(f) Voltage imbalance in three-phase (3-φ) systems causes excessive motor aging and poor

performance, and should also be checked routinely.

2-12

Previous Page

Previous Page