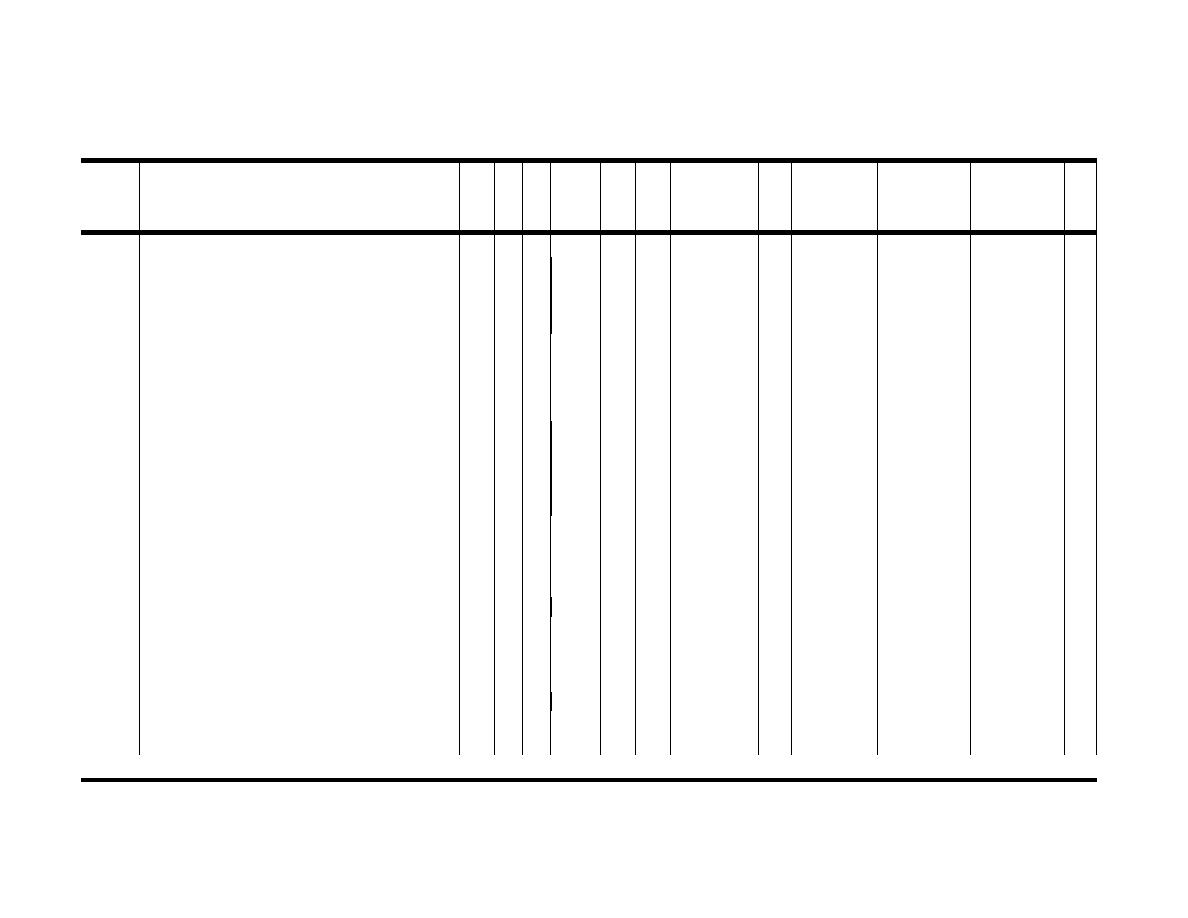

EP 1110-1-8

(Vol. 12)

31 July 03

APPENDIX D

EQUIPMENT HOURLY CALCULATION FACTORS

TIRE WEAR

EQUIPMENT

CARRIER

FOG

CATEGORY

FACTORS

FUEL FACTORS

FUEL FACTORS

FACTORS

SUB

SLV HPF

E

G

D

HPF E

G

D

E

G

FT

DT

DESCRIPTION

EK

C

DC

LIFE

D

TT RCF

C85 0.23

20

A

B

20,000

0.15

40

.400 .040 .021

0 .000 .000 .000

.000 .233 .233

0.00 0.00 0.00

0.85

LIFTING, 51 TON THRU 150 TON

C85 0.23

20

S

B

16,000

0.15

52

.520 .052 .027

0 .000 .000 .000

.000 .233 .233

0.00 0.00 0.00

0.90

LIFTING, 51 TON THRU 150 TON

C85 0.24

20

A

B

22,000

0.15

40

.400 .040 .021

0 .000 .000 .000

.000 .254 .254

0.00 0.00 0.00

0.95

LIFTING, OVER 150 TON

C85 0.24

20

S

B

18,000

0.15

52

.520 .052 .027

0 .000 .000 .000

.000 .254 .254

0.00 0.00 0.00

1.00

LIFTING, OVER 150 TON

C90 0.00

1

CRANES, MECHANICAL, LATTICE BOOM, TRUCK

MOUNTED

C90 0.01

20

A

B

14,000

0.15

50

.500 .050 .026

10 .100 .010 .005

.000 .403 .382

0.97 0.78 0.00

0.60

UNDER 26 TON

C90 0.01

20

S

B

12,000

0.15

65

.650 .065 .033

13 .130 .013 .007

.000 .403 .382

0.86 0.61 0.00

0.65

UNDER 26 TON

C90 0.02

20

A

B

16,000

0.15

50

.500 .050 .026

10 .100 .010 .005

.000 .318 .276

0.97 0.78 0.00

0.70

26 TON THRU 65 TON

C90 0.02

20

S

B

14,000

0.15

65

.650 .065 .033

13 .130 .013 .007

.000 .318 .276

0.86 0.61 0.00

0.75

26 TON THRU 65 TON

C90 0.03

20

A

B

18,000

0.20

50

.500 .050 .026

10 .100 .010 .005

.000 .318 .276

0.97 0.78 0.00

0.80

66 TON THRU 125 TON

C90 0.03

20

S

B

16,000

0.20

65

.650 .065 .033

13 .130 .013 .007

.000 .318 .276

0.86 0.61 0.00

0.85

66 TON THRU 125 TON

C90 0.04

20

A

B

20,000

0.20

50

.500 .050 .026

10 .100 .010 .005

.000 .318 .276

0.97 0.78 0.00

0.90

OVER 125 TON

C90 0.04

20

S

B

18,000

0.20

65

.650 .065 .033

13 .130 .013 .007

.000 .318 .276

0.86 0.61 0.00

0.95

OVER 125 TON

C95 0.00

20

A

B

18,000

0.20

65

.650 .065 .033

10 .100 .010 .005

.530 .318 .276

0.00 0.00 0.90

0.85

CRANES, TOWER

D10 0.00

1

DRILLS,AIR/HYDRAULIC,CRWLR MTD,0" THRU 6.5"

DIA HOLE (Add cost for drill steel and bit wear)

D10 0.10

25

A

B

14,000

0.25

80

.800 .080 .041

0 .000 .000 .000

.477 .339 .297

0.62 0.44 0.00

1.00

AIR TRACK (Add cost for drill steel and bit wear)

D10 0.20

25

A

B

10,000

0.25

80

.800 .080 .041

0 .000 .000 .000

.477 .339 .297

0.62 0.44 0.00

1.00

HYDRAULIC TRACK (Add cost for drill steel and bit

wear)

D15 0.00

25

A

B

10,000

0.25

80

.800 .080 .041

0 .000 .000 .000

.477 .339 .297

0.62 0.44 0.00

0.90

DRILLS, HORIZONTAL BORING & GROUND

PIERCING (Add cost for drill steel and bit wear)

D20 0.00

25

A

B

8,000

0.25

80

.800 .080 .041

0 .000 .000 .000

.477 .170 .254

0.00 0.00 0.00

0.85

DRILLS, CORE, COLUMN MOUNTED (Add cost for drill

steel and bit wear)

D25 0.00

25

A

B

10,000

0.25

80

.800 .080 .041

0 .000 .000 .000

.477 .170 .254

0.00 0.00 0.90

1.00

DRILLS, CORE, SKID MOUNTED (Add cost for drill

steel and bit wear)

D30 0.00

25

A

B

10,000

0.25

80

.800 .080 .041

10 .100 .010 .006

.477 .339 .297

0.67 0.57 0.80

1.00

DRILLS, EARTH / AUGER (Add cost for drill steel and

cutting edge wear)

D35 0.00

1

DRILLS, ROTARY BLASTHOLE (Add cost for drill steel

and bit wear)

EK=Economic Key (Appendix E)

LIFE=Economic Life

E=Electric Powered

FT=Front Tire

C=Operating Conditions (A=average, S=severe)

SLV=Salvage Value

G=Gas Powered

DT=Drive Tire

DC=Discount Code (B=basic 7.5%, S=special 15%)

HPF=Horsepower Factor

D=Diesel Powered

TT=Trailing Tire

RCF=Repair Cost Factor

D- 4

Previous Page

Previous Page