EP 1110-1-8

(Vol. 12)

31 July 03

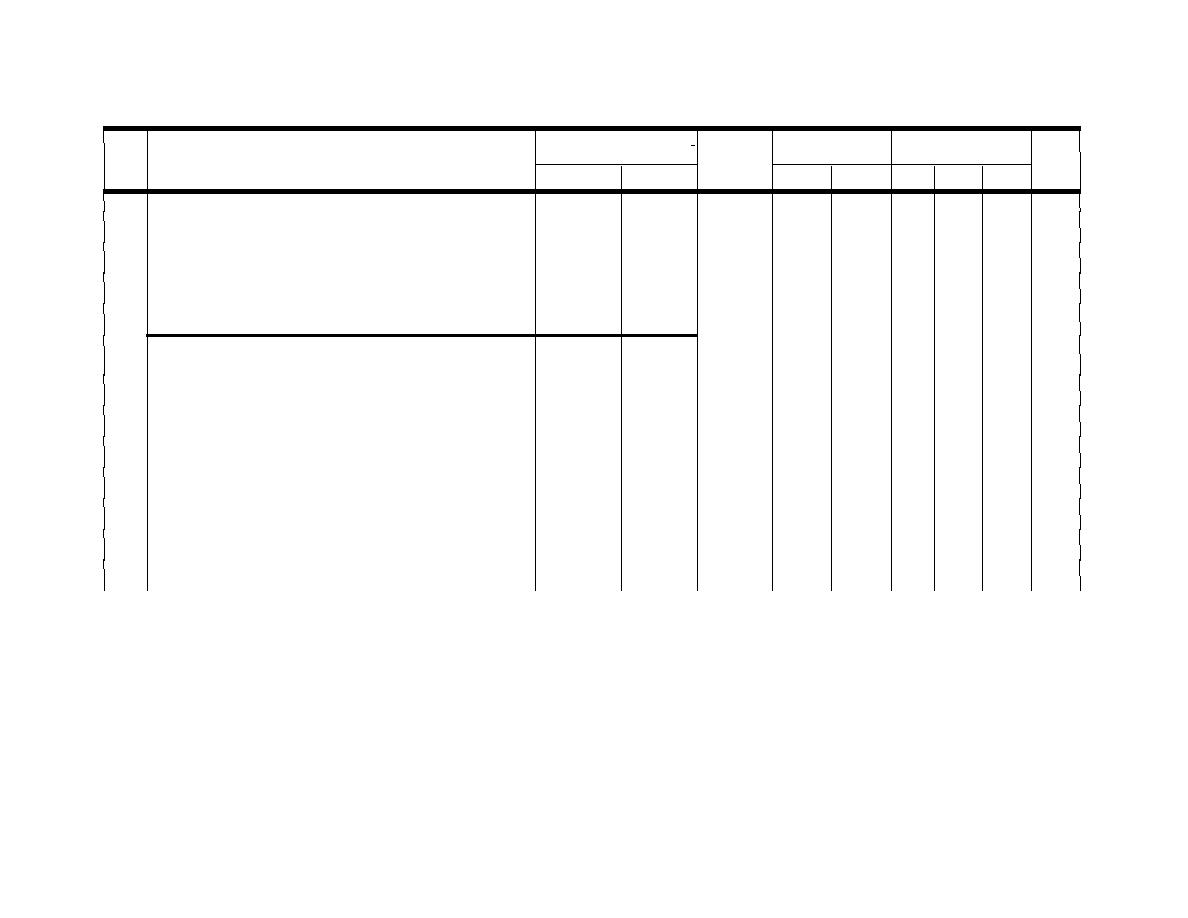

Table 2-1. HOURLY EQUIPMENT OWNERSHIP AND OPERATING EXPENSE

ENGINE HORSEPOWER

VALUE

ADJUSTABLE

TOTAL HOURLY

REGION 12

FUEL TYPE

(TEV)

ELEMENTS

RATES ($/HR)

AVERAGE STANDBY DEPR

CAT

ID.NO.

MODEL

EQUIPMENT DESCRIPTION

2000 ($)

FCCM

FUEL

CWT

MAIN

CARRIER

W35

NO SPECIFIC MANUFACTURER (continued)

W35XX023 GAS 300 DC-CC WELDER, ENGINE DRIVEN, GAS, DC-CC, 300

45 HP

G

,939

8.57

0.56

0.82

0.15

5.04

14

AMP, 3 KW, TRAILER MTD

W35XX024 DIESEL 400 DC- WELDER, ENGINE DRIVEN, DIESEL, DC-CC/CV,

48 HP

D-off

,385

6.47

0.91

1.33

0.24

2.48

21

CC/CV

400 AMP, 2-10 KW, TRAILER MTD

W35XX025 DIESEL 500 DC- WELDER, ENGINE DRIVEN, DIESEL, DC-CC/CV,

42 HP

D-off

,975

6.43

1.01

1.48

0.27

2.17

18

CC/CV

500 AMP, 4 KW, TRAILER MTD

SUBCATEGORY 0.20

ELECTRIC DRIVEN

LINCOLN ELECTRIC COMPANY

W35LC018 SP-170T

WELDER, ELECTRIC DRIVEN, 170 AMP, WIRE

5 HP

E

4

0.50

0.07

0.11

0.01

0.20

1

FEEDER

W35LC010 LINCWELD

WELDER, ELECTRIC DRIVEN, 225 AMP,

15 HP

E

5

1.01

0.04

0.06

0.01

0.59

1

225/125

STICK

W35LC019 IDEAL ARC SP- WELDER, ELECTRIC DRIVEN, 250 AMP, WIRE

11 HP

E

,253

1.22

0.19

0.30

0.04

0.43

3

225

FEEDER

W35LC011 IDEAL ARC R3R- WELDER, ELECTRIC DRIVEN, 300 AMP,

27 HP

E

,809

2.29

0.24

0.37

0.05

1.05

4

300

STICK

W35LC012 IDEAL ARC R3R- WELDER, ELECTRIC DRIVEN, 400 AMP,

35 HP

E

,841

2.78

0.24

0.38

0.05

1.37

5

400

STICK

W35LC013 IDEAL ARC R3R- WELDER, ELECTRIC DRIVEN, 500 AMP,

41 HP

E

,831

3.12

0.24

0.38

0.05

1.60

5

500

STICK

W35LC020 PROCUT 80

WELDER, ELECTRIC DRIVEN, CUTTING TORCH,

26 HP

E

,406

2.38

0.29

0.45

0.06

1.01

1

85 AMP, PLASMA

2-190

Previous Page

Previous Page