EP 1110-1-27

27 Jan 00

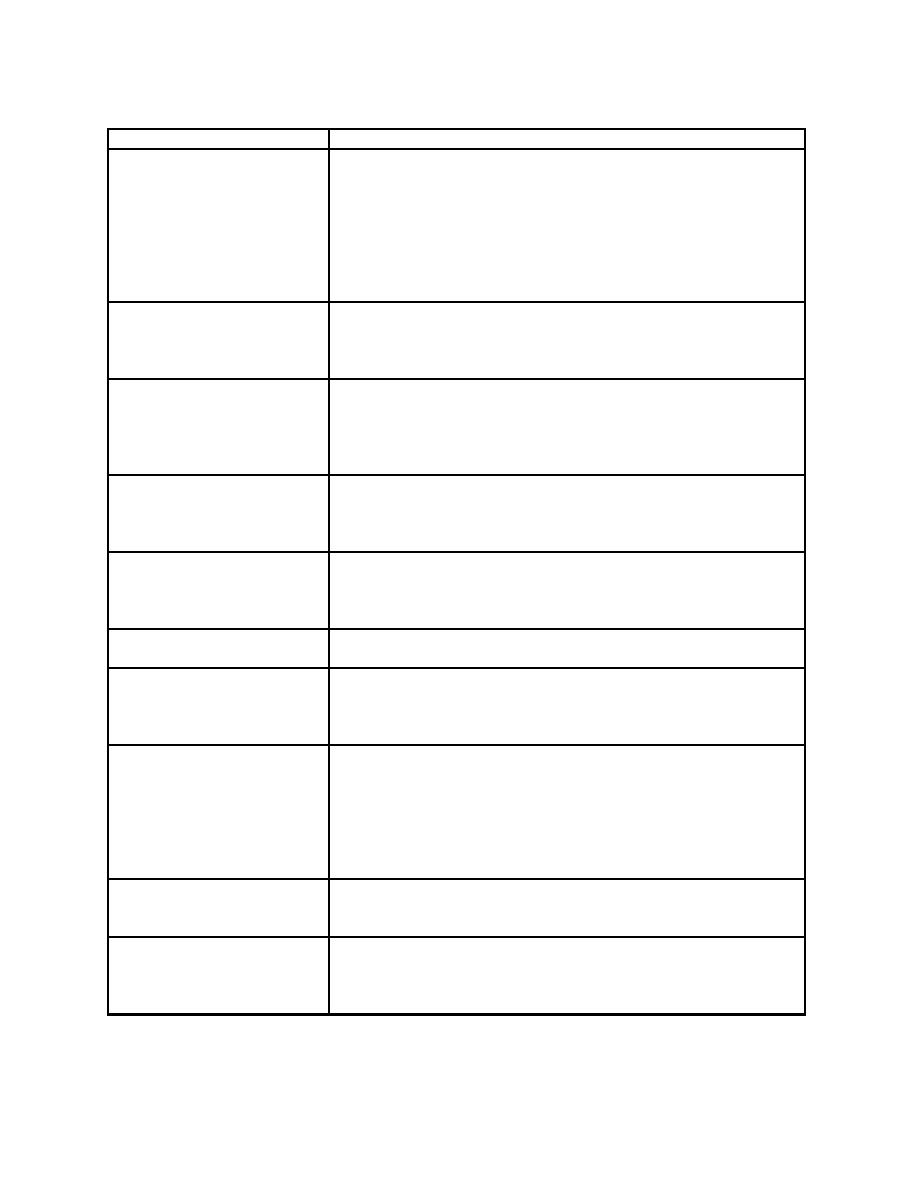

Table 2-1. Definitions of Poor Well Performance and Causes

Problems

Causes

Sand/Silt Pumping: Pump and

Inadequate screen and filter-pack selection or installation, incomplete

equipment wear and plugging.

development, screen corrosion, collapse of filter pack due to washout

resulting from excessive vertical velocity in the filter pack, presence

of sand or silt in fractures intercepted by a well completed "open-

hole," incomplete casing bottom seat (casing-screen break) or

casing-screen break due to settlement, ground movement, or poor

installation. Pumping in excess of gravel pack and system capacity

(oversized pump, pipe breakage lowering pumping head, etc.).

Silt/Clay Infiltration: Filter

Inadequate well casing seals, infiltration through filter pack, or "mud

clogging, sample turbidity.

seams" in rock, inadequate development, or casing-screen break due

to settlement, ground movement, or poor installation. Formation

material may be so fine that engineered solutions are inadequate.

Pumping Water Level

Area or regional water-level declines, pumping in excess of

Decline: Reduced yields,

sustainable well capacity, well interference, or well plugging or

increased oxidation, well

encrustation. Sometimes a regional decline will be exaggerated at a

interference, impaired pump

well due to plugging.

performance.

Injection water level rise and

Area or regional water-level rise; injection in excess of sustainable

reduced acceptance rate or

well capacity; well plugging or encrustation; encrustation, plugging,

increased injection system

or corrosion and perforation of discharge lines; increased TDH in

head.

water delivery system.

Lower (or Insufficient) Yield:

Dewatering or caving in of a major water-bearing zone, pump wear

Unsatisfactory system

or malfunction, encrustation, plugging, or corrosion and perforation

performance.

of discharge lines, increased total dynamic head (TDH) in water

delivery or treatment system.

Complete Loss of Production:

Most typically pump failure. Also loss of well production due to

Failure of system.

dewatering, plugging, or collapse.

Chemical Encrustation:

Deposition of saturated dissolved solids, usually high Ca, Mg

Increased drawdown, reduced

carbonate, and sulfate salts or iron oxides, or FeII sulfides. May

output or reduced injection

occur at chemical feed points, e.g., feeding caustic soda to raise pH

acceptance rate.

into a Ca-rich water.

Biofouling Plugging:

Microbial oxidation and precipitation of Fe, Mn, and S (sometimes

Increased drawdown, reduced

other redox-changing metals that are low solubility when oxidized)

output or reduced injection

with associated growth and slime production. Often associated with

acceptance rate, alteration of

simultaneous chemical encrustation and corrosion. Associated

samples, clogging of filters

problem: well "filter effect": samples and pumped water are not

and lines.

necessarily representative of the aquifer. Often works simultaneously

with other problems such as silting.

Pump/Well Corrosion: Loss

Natural aggressive water quality, including H2S, NaCl-type waters,

of performance, sanding, or

biofouling and electrolysis due to stray currents. Aggravated by poor

turbidity.

engineered material selection.

Well Structural Failure: Well

Tectonic ground shifting, ground subsidence, failure of unsupported

loss and abandonment.

casing in caves or unstable rock due to poor grout support, casing or

screen corrosion and collapse, casing insufficient, local site

operations.

2-2

Previous Page

Previous Page